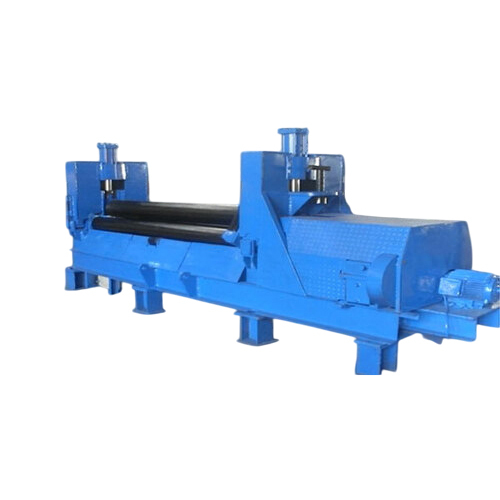

Plate Bending Machine

825000 INR/Set

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Semi Automatic

- Pressure GEAR BOX mpa

- Surface Treatment Painted

- Dimension (L*W*H) 3500X1000X1500 Millimeter (mm)

- Click to View more

X

Plate Bending Machine Price And Quantity

- 1 Set

- 825000 INR/Set

Plate Bending Machine Product Specifications

- Painted

- GEAR BOX mpa

- Electricity

- 5 TO 10 Ton/day

- BLUE

- Other

- 18 MONTH

- Other

- 3500X1000X1500 Millimeter (mm)

- 5.5 Tonne

- PLATE ROLLING

- Semi Automatic

Plate Bending Machine Trade Information

- Mumbai

- Western Union Paypal Cheque Cash in Advance (CID) Telegraphic Transfer (T/T)

- 2 Set Per Month

- 30 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- All India

- ISO

Product Description

A hydraulic plate bending machine, otherwise called a hydraulic press brake or hydraulic sheet metal bending machine, is a piece of modern hardware used to twist or shape sheet metal and plates into different points and shapes. It is a basic device in businesses like metal creation, assembling, and development for framing metal parts utilized in different applications.

Here are a few critical elements and parts of a hydraulic plate bending machine:

1. Hydraulic Framework: The hydraulic plate bending machine is controlled by a hydraulic framework that produces the power expected to twist the metal. This framework commonly incorporates a hydraulic siphon, hydraulic liquid, and hydraulic chambers.

2. Bending Instrument: The bending device, frequently called a pass on or punch, is utilized to shape the metal. The kick the bucket is fixed, while the punch moves to apply power to the metal, making it twist.

3. Control Board: Current hydraulic plate bending machines are outfitted with a control board or a PC mathematical control (CNC) framework. This permits administrators to program the ideal curve points, aspects, and different boundaries for exact and repeatable bending tasks.

4. Backgauge: Numerous hydraulic press brakes have a backgauge framework that helps position the metal precisely for each twist. This guarantees consistency in the completed item.

5. Wellbeing Highlights: Security is a pivotal part of these machines. They are frequently furnished with security gadgets, for example, light shades, crisis stop fastens, and interlock frameworks to safeguard administrators from mishaps.

6. Weight: The weight limit of a hydraulic plate bending machine alludes to the most extreme power it can apply on the metal during bending. Machines come in different weights to oblige various thicknesses and kinds of materials.

7. Bed and Smash: The machine has a bed, which fills in as a steady base, and a slam (or pillar) that moves upward to apply power to the metal. The metal is put on the bed, and the smash comes down to twist it against the pass on.

8. Material Taking care of: Some hydraulic press brakes are furnished with material taking care of frameworks, for example, transport lines, to help with moving and situating huge and weighty metal sheets.

9. Tooling: Different kinds of tooling and bites the dust are accessible to make different twist shapes and points. These can be changed to suit explicit bending prerequisites.

10. Flexibility: Hydraulic plate bending machines can twist a great many materials, including gentle steel, treated steel, aluminum, from there, the sky is the limit. They are utilized for different applications, like making sections, nooks, auto parts, and compositional components.

Uses of Hydraulic Plate Bending Machine:

1. Metal Manufacture: Hydraulic plate bending machines are widely utilized in metal creation looks for shaping different metal parts, including sections, edges, nooks, and primary components.

2. Car Industry: They are utilized in the car area for assembling vehicle parts and parts like body, sections, and fumes framework parts.

3. Aeronautic trade: Hydraulic press brakes are utilized to shape metal sheets for airplane and shuttle parts, like fuselages, wing parts, and motor parts.

4. Shipbuilding: In shipyards, these machines are utilized to twist and shape metal plates for transport bodies, decks, and other underlying parts.

5. Development: Hydraulic plate bending machines assume a critical part in the development business for bending metal sheets and plates to make underlying components like pillars, sections, and brackets.

6. Compositional Metalwork: They are utilized in building metalwork to make enriching components, railings, entryways, and other elaborate designs.

7. Central air (Warming, Ventilation, and Cooling): Hydraulic plate bending machines are utilized to manufacture ventilation work and air conditioning parts, guaranteeing accuracy in the bending system to keep up with framework effectiveness.

8. Electrical Nooks: These machines are utilized to twist and shape metal sheets for electrical nooks, cupboards, and control boards.

9. Apparatus Assembling: In the machine business, hydraulic plate bending machines are utilized for molding metal parts for things like fridges, clothes washers, and stoves.

10. Furniture Assembling: They are utilized in the creation of metal furnishings, including seats, tables, and cupboards.

11. Metal Craftsmanship: Specialists and experts utilize hydraulic plate bending machines to make perplexing metal work of art and models.

12. Oil and Gas Industry: These machines are utilized for shaping lines, pipelines, and different parts utilized in the oil and gas area.

13. Food Handling Hardware: Hydraulic plate bending machines are utilized in the manufacture of metal parts for food handling gear, like transports and blenders.

14. Clinical Gear: They are utilized in the development of metal parts for clinical gadgets and hardware.

15. Environmentally friendly power: In the sustainable power area, hydraulic plate bending machines are utilized to shape metal parts for wind turbines and sunlight based charger upholds.

16. General Assembling: These machines find applications in an extensive variety of general assembling processes where metal bending and molding are required.

FAQ:

1. What is a hydraulic plate bending machine, and how can it work?

Ans: A hydraulic plate bending machine is a modern machine used to curve or shape metal sheets and plates. It works by applying hydraulic strain to a punch (or slam), which presses the metal against a fixed pass on, making it twist.

2. What kinds of materials can be twisted utilizing a hydraulic plate bending machine?

Ans: Hydraulic plate bending machines can twist different materials, including gentle steel, hardened steel, aluminum, copper, metal, and that's just the beginning. The machine's weight limit decides the thickness and hardness of the materials it can twist.

3. What are the vital parts of a hydraulic plate bending machine?

Ans: Key parts incorporate the hydraulic framework (siphon, chambers, and liquid), a control board (frequently CNC), the bending tooling (bite the dust and punch), a bed and slam, and security highlights.

4. What is the benefit of utilizing a CNC-controlled hydraulic plate bending machine?

Ans: CNC (PC Mathematical Control) takes into account exact control and computerization of the bending system. Administrators can program explicit twist points, aspects, and arrangements, guaranteeing exactness and repeatability underway.

5. How would I choose the right weight limit with respect to my hydraulic plate bending machine?

Ans: The weight limit ought to match the thickness and hardness of the materials you plan to twist. The guideline is that the machine's weight ought to be around eight to multiple times the thickness of the material.

6. What wellbeing elements would it be a good idea for me to search for in a hydraulic plate bending machine?

Ans: Security highlights incorporate crisis stop buttons, light shades, interlock frameworks, and watchmen to safeguard administrators from mishaps during activity.

7. Could hydraulic plate bending machines handle complex bending shapes?

Ans: Indeed, they can deal with many bending shapes and points by utilizing different tooling and passes on. Custom passes on can be made to suit explicit bending necessities.

8. How would I keep a hydraulic plate bending machine?

Ans: Normal support incorporates actually taking a look at hydraulic liquid levels, reviewing hoses and fittings for spills, greasing up moving parts, and guaranteeing the machine is perfect and liberated from garbage. Adhere to the maker's support rules for explicit guidelines.

9. Are there any wellbeing safety measures I ought to take while utilizing a hydraulic plate bending machine?

Ans: Indeed, wellbeing is principal. Administrators ought to get legitimate preparation, wear proper individual defensive gear (PPE), and follow wellbeing strategies. Never sidestep wellbeing highlights or monitors.

10. Will a hydraulic plate bending machine be utilized for both limited scope and enormous scope creation?

Ans: Indeed, hydraulic plate bending machines are appropriate for both limited scope and enormous scope creation, contingent upon their weight limit and the size of the workpieces.

11. What are normal quality issues to keep an eye out for while utilizing a hydraulic plate bending machine?

Ans: Normal issues incorporate springback (the metal getting back to its unique shape subsequent to bending), wrinkling, and conflicting twist points. Appropriate tooling, material taking care of, and machine arrangement can assist with resolving these issues.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free