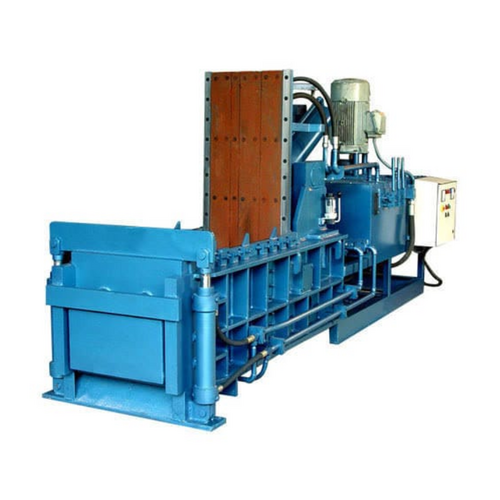

Hydraulic Scrap Bailing Machine

Product Details:

- Color Blue

- Product Type Hydraulic Scrap Baling Press

- Usage Scrap Baling Press

- Click to View more

X

Hydraulic Scrap Bailing Machine Price And Quantity

- 1 Piece

Hydraulic Scrap Bailing Machine Product Specifications

- Scrap Baling Press

- Hydraulic Scrap Baling Press

- Blue

Hydraulic Scrap Bailing Machine Trade Information

- Mumbai

- 10 Piece Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- ISO

Product Description

A hydraulic scrap baling machine, otherwise called a hydraulic scrap baler, is a piece of large equipment utilized in reusing and squander the board offices to minimized and pack different sorts of scrap materials into reasonable and movable parcels. These machines assume a critical part in the reusing business by lessening the volume of scrap materials, making them more straightforward to store, transport, and reuse. Here are a few vital viewpoints and parts of a run of the mill hydraulic scrap baling machine:

1. Hydraulic Framework: The center of the machine is its hydraulic framework, which incorporates hydraulic chambers, siphons, and valves. This framework creates the power expected to pack and smaller the scrap material.

2. Container or Transport: Scrap materials are regularly stacked onto a transport or straightforwardly into a container, which takes care of the material into the baling chamber.

3. Baling Chamber: The baling chamber is where the pressure and baling process happens. It as a rule has a platen (a level surface) that moves upward or evenly to pack the scrap material.

4. Press Plate or Smash: The press plate or slam is the part liable for applying strain to the scrap material. It pushes the material against the restricting surface of the baling chamber to minimized it into a thick parcel.

5. Bundle Ejector: After the scrap material is compacted into a parcel, a bunch ejector is utilized to push the completed bunch out of the machine for capacity or transportation.

6. Control Board: Current hydraulic scrap baling machines are outfitted with control boards that permit administrators to set and screen the baling system, including changing the pressure power and timing.

7. Wellbeing Highlights: These machines are planned with security elements, for example, crisis stop buttons and wellbeing watchmen to safeguard administrators during activity.

Hydraulic scrap baling machines are utilized for handling different kinds of scrap materials, including cardboard, paper, plastics, metals (like aluminum and steel), materials, and that's only the tip of the iceberg. They are generally utilized in reusing focuses, scrap yards, fabricating offices, and different spots where scrap materials should be proficiently handled and ready for reusing or removal.

The upsides of utilizing hydraulic scrap baling machines incorporate diminishing extra room necessities, bringing down transportation costs, and working with the reusing system, which helps in monitoring regular assets and decreasing ecological effect.

Utilizations of Hydraulic Scrap Bailing Machine:

1. Reusing Focuses: Baling machines are widely utilized in reusing offices to minimized and bundle materials like cardboard, paper, plastics, and aluminum jars for simpler capacity and transportation to reusing plants.

2. Scrap Yards: Scrap yards utilize hydraulic scrap balers to handle metal scrap, including steel, copper, and aluminum, into minimized bundles, which can be offered to metal reusing offices.

3. Fabricating Offices: Assembling plants create scrap materials during creation processes. Hydraulic balers assist with lessening waste volume and removal costs by compacting materials like plastic decorations, metal shavings, and paper squander.

4. Printing and Bundling Industry: Print shops and bundling offices use balers to pack squander paper, cardboard, and printing waste into sensible parcels, diminishing the recurrence of waste expulsion.

5. Material Industry: Material producers use balers to reduced and bundle material waste, for example, texture scraps and harmed clothing, for reusing or resale.

6. Retail and Warehousing: Retailers, particularly those with enormous amounts of cardboard bundling, use balers to pack cardboard waste produced from stock shipments and bundling materials.

7. Farming: Rural activities can utilize balers to pack agrarian waste like roughage, straw, or yield deposits into bunches for capacity and animals feed.

8. Strong Waste Administration: Metropolitan strong waste offices use balers to handle materials like plastics, paper, and aluminum jars to diminish landfill volume and upgrade squander the board.

9. E-Squander Reusing: Electronic waste (e-squander) reusing focuses utilize particular balers to minimized and get ready electronic parts and gadgets for reusing.

10. Ecological Cleanup: In a debacle recuperation or natural cleanup endeavors, balers can be utilized to productively deal with garbage and materials.

11. Auto Reusing: Auto rescue yards use hydraulic scrap balers to handle end-of-life vehicles by compacting and baling metal parts, tires, and plastics for reusing.

12. Oil and Gas Industry: Seaward and coastal penetrating activities might utilize balers to minimal and bunch materials like utilized boring mud boxes, pipes, and other scrap created during penetrating and extraction processes.

FAQ:

Q. What is a hydraulic scrap baling machine?

Ans: A hydraulic scrap baling machine is an uncompromising piece of gear used to pack and minimized different sorts of scrap materials into bundles for more straightforward stockpiling, taking care of, and transportation.

Q. What kinds of materials can be handled utilizing a hydraulic scrap baling machine?

Ans: Hydraulic scrap balers can handle a great many materials, including cardboard, paper, plastics, metals (like aluminum and steel), materials, elastic, from there, the sky is the limit.

Q. What are the primary parts of a hydraulic scrap baling machine?

Ans: The key parts incorporate a hydraulic framework (chambers, siphons, and valves), a baling chamber, a press plate or smash, a container or transport, a control board, and wellbeing highlights.

Q. What are the advantages of utilizing a hydraulic scrap baling machine?

Ans: Advantages incorporate lessening extra room necessities, bringing down transportation costs, further developing waste administration productivity, and working with reusing, which helps ration regular assets and decrease ecological effect.

Q. How does a hydraulic scrap baling machine work?

Ans: The machine's hydraulic framework creates pressure, which is applied to the scrap material in the baling chamber by the press plate or smash. This tension compacts the material into a thick parcel that is then shot out from the machine.

Q. What wellbeing highlights are ordinarily remembered for hydraulic scrap balers?

Ans: Wellbeing highlights might incorporate crisis stop buttons, security watches, interlocking instruments, and cautioning lights to safeguard administrators during activity.

Q. Are there various sorts and sizes of hydraulic scrap baling machines accessible?

Ans: Indeed, there are different sorts and sizes of hydraulic scrap balers to suit various applications and handling needs. They can go from little vertical balers to huge level balers.

Q. How would you pick the right hydraulic scrap baling machine for a particular application?

Ans: Variables to consider incorporate the sort and volume of materials to be handled, accessible space, required parcel size, and financial plan. It's fundamental to talk with producers or specialists for direction.

Q. What support is expected for hydraulic scrap balers?

Ans: Customary upkeep incorporates really looking at hydraulic liquid levels, examining hoses and seals, cleaning the machine, and tending to any wear or harm. An upkeep timetable ought to be laid out and followed.

Q. Could hydraulic scrap balers at any point be redone for explicit requirements?

Ans: Indeed, numerous producers offer customization choices to fit the machine to explicit materials or functional prerequisites.

Q. What is the ordinary life expectancy of a hydraulic scrap baling machine?

Ans: The life expectancy can shift contingent upon utilization, upkeep, and the nature of the machine. With legitimate consideration, hydraulic scrap balers can keep going for a long time.

Q. Are there any wellbeing insurances administrators ought to follow while utilizing hydraulic scrap balers?

Ans: Indeed, administrators ought to get preparing in the protected activity of the machine, wear proper individual defensive hardware (PPE), and observe security rules and methods given by the maker.

Q. What is the expense of a hydraulic scrap baling machine?

Ans: The expense changes generally relying upon the size, type, and highlights of the machine. Little upward balers can be generally reasonable, while bigger and more particular balers can be costly ventures.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free